The industrial yogurt making process can better meet the needs of modern companies for dairy manufacturing. It includes the manufacture and production of yogurt production line equipment. Shuliy machinery applies high technology and designs the yogurt production line to suit users. So, the yogurt processing line can make high-quality products, meanwhile, maintain nutrients. Before investing in a small yogurt production line, it is important to know how to build a production line in a better way. For example, to set up a 200l yogurt production line, according to our experience, we have summarized the following points for your reference.

What requirements of the 200L yogurt project?

Design capacity: 200L per day, liquid milk handling capacity.

Electric control system: push-button type or PLC full automatic, selected according to customer’s demand.

Product type: stirred yogurt or stirred yogurt?

Packing form: yogurt in cup or bag? What is the specification?

Recommended operators: milk collection and sterilization part, ingredient and process part, filling part.

We have sold a 200L yogurt line to Saudi. It was our sales manager who came up with a practical and workable solution based on the customer’s investment needs. If you want to invest in the yogurt making process industry, please call us and we will provide you with the perfect solution for your needs.

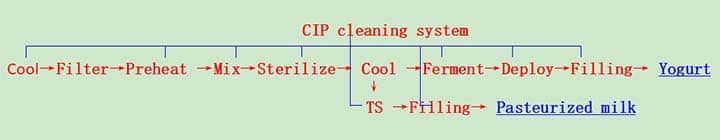

Yogurt processing flow chart

From the above flow chart, you will have a clear understanding of the yogurt making production process. Among them, TS stands for Temporary Storage.

Plant, energy, and installation requirements

Plant requirements: the area should be enough to put down the whole production line, and the height should be sufficient.

Production energy: whether the power supply meets the requirements, in addition to compressed air, water purification, etc.

Installation requirements: before the installation of equipment, you need to know the power supply cable to the power cable to each section of the electrical control cabinet for the yogurt making process. Also, you have a basic understanding of the common pipeline to the corresponding equipment, such as steam pipeline, air pressure pipeline, ice water pipeline, circulating water pipeline, water pipeline, water softening pipeline, etc.

Various specific things can be determined by both parties according to the specific situation of the workshop.

Hi

I like your mini yogurt plant but I need some more information on

1. The different parts/equipment of the process flow. A video clip of the production process

2. I would like to make yogurt in different flavours packed in 150ml, 250ml cups sealed with folio. What is the packing machine capacity.?

3.I would like to pack milk in 250ml, 500ml, and 1,000ml. What is the packing machine capacity?

4. Does your CIP system have a boiler?

5. I am interested in a 500L per day processing plant.

Please share a quotation for the above

Hello, received your information, arranged the sales manager to contact you

I am from Uganda.

Yes

W

Arranged the sales manager to contact you, she will contact you so soon.

Hello,

I live in Nigeria. I work in Food Science Department of a university and we are interested in setting up a small-scale Yoghurt Production plant that can handle 150-200 Litre drink yoghurt. This set up is okay except that there should be a filler that will be able to dispense into tetrapack of 100ml, 250ml and 500ml circa.

Can you forward to me the equipment and financial implications of setting it up and other requirements.

Thanks

Hello, thanks for yorur inquiry. I have informed professional maanger to send machine details and price to you, pls attention email from shuliy

Hola buenos días, estoy interesada en saber de una planta de producción de 500 litros de yogur batido que contenga mermelada. Nos encantaría que nos envíe la información de las maquinarias y el costo de cada una de ellas. Muchas gracias

Hola, le he informado a un gerente profesional para que le envíe los detalles de la máquina y el precio. Por favor, envíe un mensaje de atención de Shuliy.