Shuliy yogurt production line is composed of professional milk processing equipment for making plain and flavored yogurt, which is specially designed for most yogurt producers with different yogurt production scales. Our commonly sold yogurt production lines are the 500L/1000L/2000L/5000L yogurt processing plants. These yogurt machines have low prices and high efficiency so that they are always applied in beverage stores, dairy processing plants, snack shops, pastures, cake houses, and other fields.

Yogurt process flow of the commercial yogurt makers

- Fresh milk as raw materials:

Fresh milk cold-storage(about 4℃ keeping)——Milk filtering(removing impurities)——Milk preheating(about 45℃)——Milk homogenizing(55-70℃/20-25MPa)——Milk sterilizing(pasteurization or high temperature sterilization)——Sterilized milk cooling(43-45℃)——Adding related bacteria species and additives ——Yogurt fermenting(needs about 6-8 hours)

- Milk powder as raw materials:

Milk powder mixing and preheating with water——High-speed fine mixing——Milk preheating——Milk homogenizing(55-70℃/20-25MPa)——Milk sterilizing(pasteurization or high-temperature sterilization)——Sterilized milk cooling(43-45℃)——Adding related bacteria species——Yogurt fermenting(needs about 6-8 hours)

The basic requirements for producing yogurt

- Raw materials: fresh milk or milk powder

| Indicators | Defatted milk | Whole milk | |

| Fat | 0.05% | 0.05-3.5% | |

| Protein | 2.75-3.7% | ||

| Casein | >2.4% | ||

| Lactose | 4.5-5.0% | ||

| Total bacteria | <10000 |

- Beneficial bacteria species: Bifidobacterium bifidum, Lactobacillus acidophilus, Lactobacillus bulgaricus, Streptococcus thermophilus and so on.

- Milk sterilization temperature: about 85℃ or with a high-temperature of about 125℃.

- Yogurt fermenting temperature and time: 43℃ for 6-8 hours.

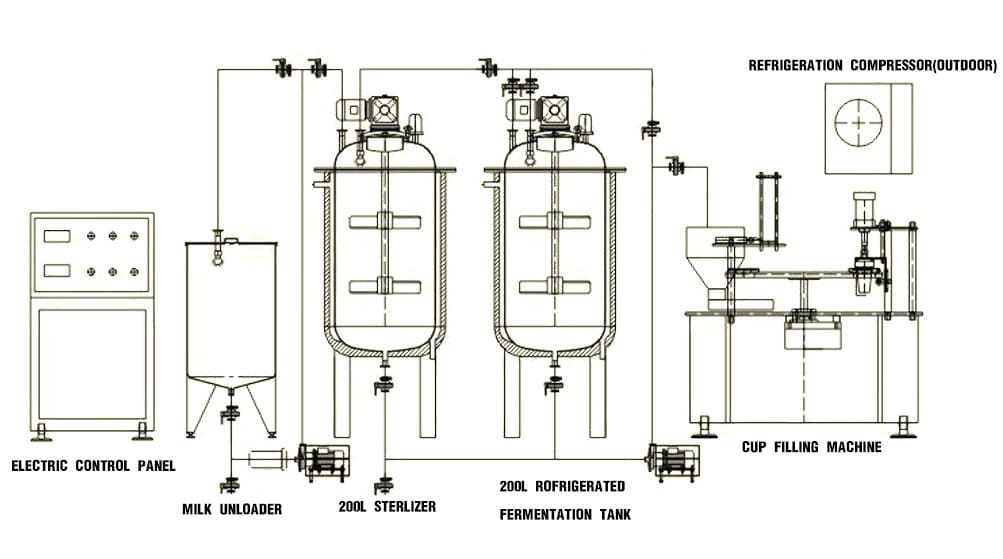

Detailed components of the automatic yogurt production line

The whole set of yogurt processing line is mainly composed of a series of yogurt production tanks which are connected by stainless pipes and adjustable pumps. No matter what the customers’ yogurt production requirements are, we can collocate the most suitable machines and customize the production lines for them. The hot-sale daily yogurt processing yields with Shuliy yogurt maker machines are 500L/D 1000L/D and 2000L/D.

- Cold-storing of milk

The fresh milk collected from pastures should be refrigerated in a timely manner. The low-temperature refrigerated tank is equipped with a special compressor, which can provide fresh milk with a fresh temperature of about 4℃, which can ensure that the milk does not deteriorate for a long time.

- Milk filtering for removing impurities

The dedicated double-layer filter or single-layer filter can effectively filter out impurities in milk. The three-dimensional screen device in the filter can quickly remove impurities such as hair or other residues in the milk.

- Milk preheating with 45℃

The preheating tank is designed with the jacket-structure where can be injected water for heating the inner milk. The heating method adopts electric heating. Inside of the milk preheating tank, there is a mixer shaft for mixing the milk when preheating, which can make sure that the milk is preheated evenly. After preheating, the milk temperature is about 45℃.

- Milk homogenizing

The preheated milk will be extracted into the milk homogenizer for further processing. Under the processing conditions of 50-70℃ in temperature and 20-25MPa in pressure, the macromolecular and fat balls will be refined into small particles, which can ensure the good tastes of the final yogurt.

- Milk sterilizing and cooling

The sterilization tank also has the double-layer structure which can heat the water with high temperature for milk sterilizing. This milk sterilizing link is very important for killing most of the bacteria in the milk and ensure the final yogurt quality. The whole milk sterilizing process will last about 40 minutes. When the milk temperature reaches about 85℃, the milk sterilization will be finished. Then we discharge the hot water and inject the cold water(with room temperature) for cooling.

- Adding bacterial species and additives

When the milk temperature cooling down(about 43-45℃), we can add the related bacterial species and the additives. The users can add these materials based on their own yogurt processing recipes or their requirements for the flavored yogurt production.

- Yogurt fermentation

The last step for making yogurt is fermenting the milk for about 6-8 hours. The yogurt fermenting temperature is about 45℃. And during the fermentation process, there will occur the lactic acid bacteria that are good for the human body.

- Automatic yogurt packaging

After the yogurt fermentation is finished, we can use the automatic filling and packing machine to dispense the yogurt into cups, or bottles. The yogurt filling machine has the multifunctions for filling yogurt into cups or bottles quantitatively and automatic putting bottle caps or sealing. After packaging, these yogurt products can be sold to the market.

- Automatic cleaning system for yogurt production line

This cleaning system also named the CIP washing system, which is composed of three stainless-steel tanks. These tanks are separately filled with clean water, acid water, and alkali water, which can clean the whole yogurt production line deeply within only several minutes.

Main features of the commercial yogurt production line

- To ensure food safety and hygiene, the whole line is made of the high-quality SUS 304 stainless steel which can make sure all these yogurt processing machines are durable, corrosion-resistant and wear-resistant.

- The working capacities of the yogurt production line can be customized with our technicians according to the customers’ requirements. Each of the tanks in the line can be different models so that the daily total yield for making yogurt is adjustable.

- As the professional yogurt maker manufacturer and supplier, we have the strength for providing our clients with the best machines and related solutions, such as yogurt processing plant designing, investment and cost analysis, yogurt production guiding and so on.

I want to request for a quotation of a mini yoghurt production line. Thanks

I want to request for a quotation of a mini yoghurt production line. Thanks

Hello, thanks for yorur inquiry. I have informed professional maanger to send machine details and price to you, pls attention message from shuliy

حياكم الله

اريد تزويدي بالاسعار خط انتاج الزبادي

مع التفاصيل

واتساب

00967733235333

ارجو سرعة الرد

عاصم الناجي

مرحبًا، لقد استلمتها ورتبت مع مدير المبيعات المحترف لدينا لإرسال تفاصيل الماكينة والسعر إليك. يرجى الانتباه إلى البريد الإلكتروني من Shuliy.

Info 50247305643

Hello, I have received it and coordinated with our professional sales manager to send you the details and price of the machine. Please pay attention to Shuliy’s email.

Please give me a comprehensive quote for a 200 liter complete production line for yoghurt. Thank u.

Kindly e mail me a quotation for a mini yogurt production company.

Can i get design of a single unit and quotation?

please be urgent.

thanks

Pls I need one of the yoghurt machine urgent pls contact; 0243720862 / 0560572756 thanks

Bonjour

Je suis intéressé par une ligne complète pour la fabrication de yaourts à boire a ba0se de lai de vache

I want to know whether i can be able to get a 500L yoghurt production line and it’s price please.

Nice to receive your inquiry dear. I have contacted you via WhatsApp and email, please check.

I need a quotation for a 300litre and 500liters production line with special preference for Greek yogurt.

My email is walelawon@gmail.com

Nice to receive your inquiry dear. I have contacted you via WhatsApp and email, please check.

How much does a 300L yogurt plant cost.

Need a yogurt filling station and packaging station also

Nice to receive your inquiry dear. I have contacted you via WhatsApp and email, please check.

Hi I need a quotation for 200 liter complete from a-z.

Nice to receive your inquiry dear. I have contacted you via WhatsApp and email, please check.

Can I get quote for 200L, 300L, 500L and 1000L

Nice to receive your inquiry dear. I have contacted you via WhatsApp and email, please check.

Please can I get the quotation 200 liter yoghurt production line

Nice to receive your inquiry dear. I have contacted you via WhatsApp and email, please check.

Please, send me a quotation for 500L per day complete yoghurt plant. I urgently need this quotation

Nice to receive your inquiry dear. I have contacted you via WhatsApp and email, please check.

I need quotation for a set of yoghurt production line, 500ltr capacity.

Nice to receive your inquiry dear. I have contacted you via WhatsApp and email, please check.

I need a quotation for a 5-ton/day production line with a special preference for peach yoghurt.

Please sent me an email: kelseyzhao126@gmail.com

Thanks for your inquiry, I have contacted you via email, please have a check.

How much does a complete 200ltr yoghurt plant cost?

contact me via watsap +254705910069

Thanks for your inquiry, I will contact you asap, please have a check.

Hi

I need to have a more detailed conversation with this company.

Kindly respond

As I understand that there are 8 separate machines that should be used in a yogurt factory.

I have a few questions about making yogurt.

Also, how much does a full 100 liter yogurt factory cost?

Contact: eylulguven57@gmail.com

Thank you

Thanks for your inquiry. Our sales staff will send you machine details later.

Please, send me a quotation for 500L, 300L, 200L and 150L per day complete yoghurt plant. I urgently need this quotation

Thanks for your inquiry.

Thanks for your inquiry. I also received your email, arranged the sales manager to send the relevant quotation

Please can I get the quotation 5000 liter per day yogurt production line

Hello, thanks for your inquiry. I have informed and arranged the sales manager to contact you, pls attention to your email.

Please, send me a quotation for 500L, 300L, 200L and 150L per day complete yoghurt plant. I urgently need this quotation

Hello, we have talked on whatsapp also, I have informed professional manager to send machine details and price to you, pls attention message from shuliy

I need an offer for a 300 liter production and packaging line with a particular preference for Greek yogurt. my email is giannisxd@gmail.com

Hello, I have informed professional manager to send machine details and price to you, pls attention message from shuliy

Veuillez m’envoyer par e-mail un devis pour une mini entreprise de production de yaourt. C’est urgent

Bonjour, j’ai informé le responsable professionnel de vous envoyer les détails et le prix de la machine, veuillez noter le message d’attention de Shuliy.

Quiero saber el precio de la línea de producción de yogurt de capacidad de 3 000 litros

Hola, le he informado a un gerente profesional para que le envíe los detalles de la máquina y el precio. Por favor, envíe un mensaje de atención de Shuliy.

احتاج الى مواصفات و عرض سعر الماكينه تعبئه الزبادي

مرحبًا، لقد أبلغت المدير المحترف بإرسال تفاصيل الماكينة وسعرها إليك، يرجى الانتباه إلى رسالة من shuliy

Veuillez me donner un devis complet pour une ligne de production complète de yaourt de 200 litres. Merci.

Bonjour, j’ai informé notre directeur des ventes professionnel de vous envoyer les détails et le prix de la machine, veuillez noter le message d’attention de Shuliy.

Quotation of 1000L yogurt complete

Plant per day I want to start

Hello, I have informed our professional sales manager to send machine details and price to you, pls attention message from shuliy.

Bonjour

Je veux avoir un devis pour la ligne de fabrication de yaourt 500l et1000l

Cordialement

Bonjour, merci pour votre demande et j’ai informé notre directeur des ventes professionnel de vous envoyer les détails et le prix de la machine, veuillez noter le message d’attention de Shuliy.

Buenas quisiera cotizar la línea de fabricación de yogurt de 3000 litros por día y también algún detalle sobre la velocidad nominal por maquinaria o proceso por favor

Hola, gracias por su consulta y le he informado a nuestro gerente de ventas profesional para que le envíe los detalles de la máquina y el precio. Por favor, envíe un mensaje de atención de shuliy.

في انتظار التفاصيل

حسنًا، فهمت، سوف أتحقق

السلام عليكم اولا شكرا علي المعلومه المفصله وارجو

اعلامي عن تكاليف خط انتاج زبادي كاملا سعه 200l وشكرا

مرحبًا، لقد استلمتها وأبلغت مدير المبيعات المحترف لدينا بإرسال تفاصيل الماكينة والسعر إليك. يرجى إرسال رسالة انتباه.

I need quotation for a 500l yohurt production machine

Hello, I have received it and arranged our professional sales manager to send you the machine details and price. Please pay attention to the email from Shuliy.

أريد أن أعرف ما إذا كان بإمكاني الحصول على خط إنتاج زبادي سعة 500 لتر وسعره من فضلك.

رد

مرحبًا، لقد استلمتها واتصلت بمدير المبيعات المحترف لدينا ليرسل لك تفاصيل الجهاز وسعره. انتبه إلى البريد الإلكتروني لـ Shuliy.

Por favor me gustaría recibir cotizacación sobre una linea de producción pequeña. 200 litros.

Hola, lo he recibido y me he puesto en contacto con nuestro gerente de ventas profesional para enviarte los detalles y el precio de la máquina. Presta atención al correo electrónico de Shuliy.

Bonjour,

Je souhaite demander un devis pour une mini ligne de production de yaourt pour une surface 300 m2 couverte?

Merci

Hola, lo he recibido y me he puesto en contacto con nuestro gerente de ventas profesional para enviarte los detalles y el precio de la máquina. Presta atención al correo electrónico de Shuliy.

السلام عليكم ورحمة الله وبركاتة

نحن شركة جديدة في مدينة عدن اليمن نريد شراء خط انتاج الزبادي لذلك نريد منكم عرض سعر

ولكم خالص التحية

مرحبًا، لقد استلمتها واتصلت بمدير المبيعات المحترف لدينا ليرسل لك تفاصيل الجهاز وسعره. انتبه إلى البريد الإلكتروني لـ Shuliy.

hola, queria mas informacion para una linea de produccion de 100L de yogur, y la cotizacion

Hola, lo recibí y contacté con nuestro gerente de ventas para enviarle los detalles y el precio de la máquina. Por favor, siga el correo electrónico de Shuliy.