Before operating a small yogurt production line, make sure you are familiar with and understand the equipment’s operating manual and safety procedures. Based on our experience, we have briefly described the basic steps of a small-scale yogurt production line, the equipment used and how to operate it.

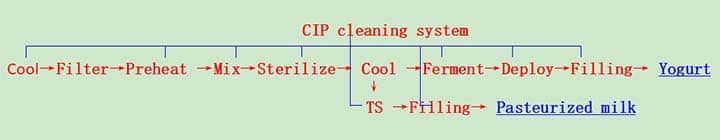

Basic process of the small yogurt production line

The basic production process of yogurt: raw milk storage → filtration → preheating → homogenization → sterilization → fermentation → filling.

List for small yogurt production line equipment

Yogurt process supporting equipment: raw milk cooling tank (storage) → single filter (100 mesh) → milk pump → preheating tank (40-50 degrees 20min) → milk pump → homogenizer (300L 1h) → sterilization tank (40-85 30min 300l 300L more than 1h 40min cooling) → pump → fermentation tank (42 degrees 8h) → pump → filling machine

Yogurt processing introduction

- The customer will store the whole fresh milk in the raw milk tank, through the special stainless steel milk pump to pump the raw milk into the pasteurization tank for preheating. If the amount of raw milk is relatively large, you can directly pour the raw milk into the preheating tank.

- After the preheating is completed, the preheated milk needs to be pumped into the homogenizing tank through the stainless steel milk pump, and the raw milk will be homogenized through the work of the homogenizing pump, and the taste and color of the fresh milk will be more remarkable after the homogenization.

- When sterilization is needed, the centrifugal milk pump connecting the homogenization tank and the pasteurization tank is turned on, and pasteurization is carried out through 350# heat-conducting oil or hot water. According to different heat sources, output, seasons and other factors to differentiate, the pasteurization time is generally about 0.5 to 1.5 hours, and the pasteurization temperature is 85℃.

- After the sterilization is completed, the fresh milk is pumped into the fermentation tank through the milk pump. The pre-cooling tank and the fermentation tank are in the same tank, and the pre-cooling process is to use cold water for pre-cooling, the cooling time is about 0.3 to 0.5 hours, and the temperature is usually cooled down to 45℃, the strain is added and the fermentation is turned on.

- After the fermentation is completed, the filling machine is turned on to fill and seal the yogurt.

سلام عليكم ….

بستفسر من خط انتاج الزبادي الجامد بطاقة انتاجية بسيطة مع اماكنية زيادة الانتاجية بالتعديل عليه و شكراً

مرحبًا ، شكرًا على استفسارك وقد أبلغت مدير المبيعات المحترف لدينا لإرسال تفاصيل الماكينة والسعر إليك ، يرجى الانتباه رسالة من شولي.