Mstari wa uzalishaji wa mtindi wa Shuliy una aina mbalimbali za vipimo vya bidhaa. Vifaa vya mstari wa uzalishaji kawaida hulinganishwa kulingana na matokeo yanayolingana, kama vile 200L/D, 300L/D, 500L/D, 1000L/D hata hapo juu. Uwezo tofauti wa uzalishaji wa mtindi, vifaa vyao vya uzalishaji vinavyolingana, na teknolojia ya uzalishaji pia ina tofauti.

Vipengele vya kiwanda cha kusindika mtindi uliogandishwa kibiashara

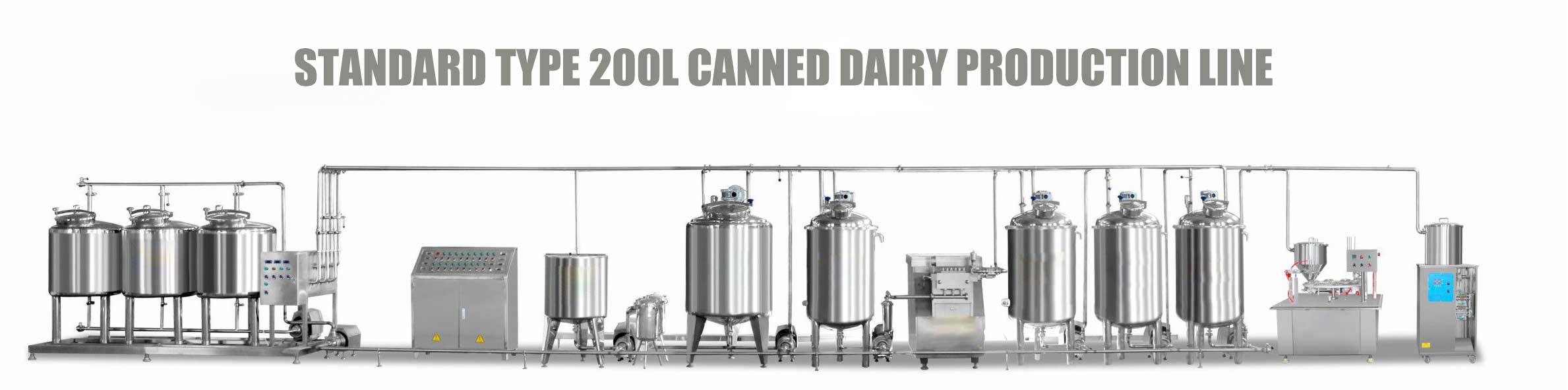

Mstari wa uzalishaji wa mtindi wa kawaida unajumuisha mfululizo wa vitengo vya usindikaji wa mtindi vinavyotumika kutengeneza mtindi wa kawaida na bidhaa za mtindi zenye ladha mbalimbali. Mstari wa jumla mstari wa usindikaji wa mtindi ni mstari kamili wa uzalishaji, kila kifaa kinahusishwa na mabomba, mchakato mkuu wa uzalishaji unajumuisha filtration, kuupasha joto, sterilization, homogenization na fermentation, na michakato mingine ya usindikaji ili kubadilisha maziwa fresh kuwa mtindi. Mstari mzima unaweza kubinafsishwa kulingana na mahitaji halisi ya mteja.

Kwa nini mteja wa Saudi anatuchagua?

Mteja wa Saudia alikuwa Uchina kwa Maonyesho ya Canton, na yeye na washirika wake wa kibiashara walitaka kupata fursa nzuri ya biashara ili kupata pesa. Walikuwa wakifikiria kuwekeza katika usindikaji wa chakula kwa muda mrefu, kwa hivyo yeye na washirika wake walikuja Uchina wakati wa Maonyesho ya Canton kununua mashine bora za chakula. Alipata tovuti yetu wakati akitafuta habari kuhusu usindikaji wa mtindi na akawasiliana nasi kupitia nambari ya WhatsApp tuliyoacha kwenye ukurasa.

Dette er første gang kunden har investert i maskineri og utstyr, så han er mer forsiktig. Vår salgsleder ga dem en anbefalt minimumsproduksjon av yoghurtproduksjonslinje, med en daglig produksjon på omtrent 200L. Vi foreslo at kundene kan starte med en liten produksjonslinje, og hvis produksjonseffektiviteten er god, kan de utvide yoghurtproduksjonen. Kunden er enig i vårt forslag. Vi utarbeidet raskt et tilbud for hele produksjonslinjen og sendte det til kundene våre i tide.

Pia tulimwalika mteja huyu na mshirika wake kutembelea kiwanda chetu kwa kutembelea tovuti. Baada ya kusoma nukuu ya mashine hiyo, mteja aliamua kutembelea kiwanda chetu baada ya kujadiliana na mshirika wake. Wakati wa ziara ya kiwanda chetu cha kutengeneza mashine ya kutengeneza mtindi, waliuliza kwa kina kuhusu nyenzo za mashine hiyo na baadhi ya maswali ya baada ya mauzo. Wahandisi wetu waliwaonyesha tofauti kati ya vifaa tofauti vya mashine, na pia aliwaelezea kwa nini mashine za sura sawa ni tofauti kwa bei. Wateja wa Saudi waliridhishwa na huduma zetu za kitaalamu na ubora wa mashine na hatimaye walitupa agizo la kiwanda hiki kidogo cha kusindika mtindi.